Forth Bridge

| Forth Bridge | |

|---|---|

|

|

| Carries | Rail traffic |

| Crosses | Firth of Forth |

| Locale | Edinburgh, Inchgarvie and Fife, Scotland |

| Maintained by | Balfour Beatty under contract to Network Rail |

| Designer | Sir John Fowler and Sir Benjamin Baker |

| Design | Cantilever bridge |

| Total length | 2,528.7 metres (8,296 ft) |

| Longest span | 2 of 521.3 m (1710 ft) |

| Clearance below | 46 metres (151 ft) |

| Opened | 4 March 1890 |

| Daily traffic | 190–200 trains per day |

|

|

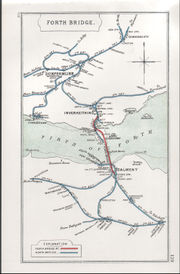

The Forth Bridge is a cantilever railway bridge over the Firth of Forth in the east of Scotland, to the east of the Forth Road Bridge, and 14 kilometres (9 mi) west of central Edinburgh. It was opened on 4 March 1890. It is often called the Forth Rail Bridge or Forth Railway Bridge to distinguish it from the Forth Road Bridge although this is erroneous: it having been called the "Forth Bridge" since its construction and having for over seventy years the sole claim to this name. The bridge connects Scotland's capital city, Edinburgh, with Fife, leaving the Lothians at Dalmeny and arriving in Fife at North Queensferry; it acts as a major artery connecting the north-east and south-east of the country. Described in the Collins Encyclopaedia of Scotland as "the one immediately and internationally recognised Scottish landmark",[1] it may be nominated by the British government to be added to the UNESCO World Heritage Sites in Scotland.[2] The bridge and its associated railway infrastructure is owned by Network Rail Infrastructure Limited. Until 1917, when the Quebec Bridge was completed, it was the longest cantilever bridge in the world. The Forth Bridge remains the second longest.[3][4]

Contents |

History

Construction of an earlier bridge, designed by Sir Thomas Bouch, got as far as the laying of the foundation stone, but was stopped after the failure of another of his works, the Tay Bridge. Bouch had proposed a suspension bridge but the public inquiry into the Tay bridge disaster showed that he had under-designed the structure and mistakenly used cast iron, which weakened the entire structure. The project was handed over to two other Englishmen Sir John Fowler and Sir Benjamin Baker, who designed a structure that was built by Glasgow based company Sir William Arrol & Co. between 1883 and 1890. Baker – "one of the most remarkable civil engineers Britain ever produced" – and his colleague Allan Stewart received the major credit for design and overseeing building work. During its construction, over 450 workers were injured and 98 lost their lives.

First steel structure

The bridge was built in steel alone, the first bridge in Britain to use that material.[5] It was the first major structure in Britain to be constructed of steel;[6] Its contemporary, the Eiffel Tower was built of wrought iron.

Large amounts of steel had become available only after the invention of the Bessemer process in 1855. Until 1877 the British Board of Trade had limited the use of steel in structural engineering because the process produced steel of unpredictable strength. Only the Siemens-Martin open-hearth process developed by 1875 yielded steel of consistent quality. The 64,800 tons of steel needed for the bridge was provided by two steel works in Scotland and one in Wales.[5]

Construction

The bridge is, even today, regarded as an engineering marvel.[7] It is 2.5 km (1.5 miles) in length, and the double track is elevated 46 m (approx. 150 ft) above high tide. It consists of two main spans of 521.3 m (1,710 ft), two side spans of 207.3 m, and 15 approach spans of 51.2 m (168 ft).[8] Each main span comprises two 207.3 m (680 ft) cantilever arms supporting a central 106.7 m (350 ft) span truss. The three great four-tower cantilever structures are 100.6 m (330 ft) tall,[9] each 70 ft (21 m) diameter foot resting on a separate foundation. The southern group of foundations had to be constructed as caissons under compressed air, to a depth of 90 ft (27 m). At its peak, approximately 4,600 workers were employed in its construction. Initially, it was recorded that 57 lives were lost; however, after extensive research by local historians, the figure was increased to 98.[10] Eight men were saved by boats positioned in the river under the working areas.

Hundreds more were left crippled by serious accidents, and one log book of accidents and sickness had 26,000 entries. In 2005, a project was set up by the Queensferry History Group to establish a memorial to those workers who died during the bridge's construction. In North Queensferry, a decision was also made to set up memorial benches to commemorate those who died during the construction of both the rail and the road bridges, and to seek support for this project from Fife Council.

More than 55,000 tons of steel were used, as well as 18,122 m3 of granite and over eight million rivets. The bridge was opened on 4 March 1890 by the Prince of Wales, later King Edward VII, who drove home the last rivet, which was gold plated and suitably inscribed.[11] A recent materials analysis of the bridge, c. 2002, found that the steel in the bridge is of good quality, with little variation[12]

The use of a cantilever in bridge design was not a new idea, but the scale of Baker's undertaking was a pioneering effort, later followed in different parts of the world. Much of the work done was without precedent, including calculations for incidence of erection stresses, provisions made for reducing future maintenance costs, calculations for wind pressures made evident by the Tay Bridge disaster, the effect of temperature stresses on the structure, and so on.

Where possible, the bridge used natural features such as Inchgarvie, an island, the promontories on either side of the firth at this point, and also the high banks on either side.

The bridge has a speed limit of 50 mph (80 km/h) for passenger trains and 20 mph (32 km/h) for freight trains. The weight limit for any train on the bridge is 1,422 tonnes (1,442,000 kg) although this was waived for the frequent coal trains which used the bridge prior to the reopening of the Stirling-Alloa-Kincardine railway, provided two such trains did not simultaneously occupy the bridge. The route availability code is RA8, meaning any current UK locomotive can use the bridge, which was designed to accommodate heavier steam locomotives.

Up to 190–200 trains per day crossed the bridge in 2006.[13]

Maintenance

A structure like the Forth Bridge needs constant maintenance and the ancillary works for the bridge included not only a maintenance workshop and yard but a railway "colony" of some fifty houses at Dalmeny Station. The track on the bridge is of "waybeam" construction: 12 inch square baulks of timber 6 metres long are bolted into steel troughs in the bridge deck and the rails are fixed on top of these sleepers. In 1992 the bridge was re-railed with standard BS113A rail (54 kg/m). Prior to 1992 the rails on the bridge were of a unique "Forth Bridge" section.

Although modern trains put fewer stresses on the bridge than the earlier steam trains, the bridge needs constant maintenance, and this is currently undertaken by Balfour Beatty under contract to Network Rail.[14]

"Painting the Forth Bridge" is a colloquial expression for a never-ending task, coined on the erroneous belief that, at one time in the history of the bridge repainting was required and commenced immediately upon completion of the previous repaint.[15] According to a 2004 New Civil Engineer report on modern maintenance, such a practice never existed, although under British Rail management, and before, the bridge had a permanent maintenance crew.

A recent repainting of the bridge commenced with a contract award in 2002, for a schedule of work which was expected to continue until March 2009, but as of August 2010 is still ongoing. This involves the application of 20,000 m2 of paint at an estimated cost of £13M a year. This new coat of paint is expected to have a life of at least 25 years, and perhaps as long as as 40, thus removing the need for constant repainting.[16] The work involves blasting all previous layers of paint off the bridge for the first time in its history, allowing for repairs to be made to the steel.[16][17][18] In 2008 the estimated cost was increased to £180M, and projections for finishing the job to 2012.[19]

In a report produced by JE Jacobs, Grant Thornton and Faber Maunsell in 2007 which reviewed the alternative options for a second road crossing, it was stated that "Network Rail has estimated the life of the bridge to be in excess of 100 years. However, this is dependant [sic] upon NR’s inspection and refurbishment works programme for the bridge being carried out year on year".[20]

Competition

The Forth Road Bridge is another popular crossing of the Firth.

In 2007, in a two week trial jointly funded by SEStran and StageCoach, a passenger hovercraft ran between Kirkcaldy and Edinburgh[21], but Stagecoach have indicated that they are not interested in developing this into a service.[22]

The new Stirling-Alloa-Kincardine rail link will divert coal trains away from the bridge. Instead they will travel via Stirling to Longannet Power Station. Freight restrictions may then be lifted, with the potential of increasing the number of trains from 10 tph (trains per hour) to 12.

Banknotes, coins

A representation of the Forth Bridge appears on the 2004 Issue one pound coin.[23]

The 2007 series of banknotes issued by the Bank of Scotland depicts different bridges in Scotland as examples of Scottish engineering, and the £20 note features the Forth Bridge.[24]

Popular culture

- The first German air attack on Britain in WWII took place over the Forth Bridge. 6 weeks into the war, on 16 October 1939, German bombers launched an attack on Rosyth naval base. RAF 603 "City of Edinburgh" Spitfire squadron shot down the first German planes over Britain during the attack.[25]

- There is a scene on the bridge in Alfred Hitchcock's 1935 film The 39 Steps and it is featured even more prominently in the 1959 remake of the same film, although there is no reference to the bridge in the book by John Buchan upon which the films are based.

- The bridge featured in posters advertising the soft drink Barr's Irn Bru, with the slogan: Made in Scotland, from girders

- The bridge was lit up red for BBC's Comic Relief in 2005.

- A countdown clock to the millennium was placed on the bridge in 1998.

- The Bridge, a novel by Iain Banks, is mainly set on a fictionalised version of the bridge.

- In Alan Turing's most famous paper about artificial intelligence, one of the challenges put to the subject of an imagined Turing test is "Please write me a sonnet on the subject of the Forth Bridge". The test subject in Turing's paper answers, "Count me out on this one. I never could write poetry".[26]

- Sebastien Foucan, a French freerunner, crawled along one of the highest points of the bridge, without a harness, for the Jump Britain documentary made by Channel 4.

- Linus points out the bridge from the airplane in the 1980 Peanuts film, Bon Voyage, Charlie Brown (And Don't Come Back!!) as they approached Heathrow Airport. The Forth Bridge is 273 nautical miles (506 km) north of Heathrow, and is often visible on the approach to Edinburgh Airport.

- In World War I returning British sailors would time their departures or returns to the base at Rosyth by asking when they would pass under the bridge.[27] This practice continued at least up to the 1990s.

- The bridge is included in the video game Grand Theft Auto: San Andreas by Edinburgh-based developer Rockstar North. Renamed the Kincaid Bridge, it serves as the main railway bridge of the fictional city of San Fierro, and appears alongside a virtual Forth Road Bridge.[28]

References

- ↑ Keay, John; Keay, Julie (2000). Collins Encyclopaedia of Scotland. London: HarperCollins. p. 409. ISBN 0002550822.

- ↑ UNESCO - UK Tentative List Retrieved 10.01.2009.

- ↑ DeLony, Eric (1996). "Context for World Heritage Bridges". Paris: International Council on Monuments and Sites. http://www.icomos.org/studies/bridges.htm. Retrieved 2 September 2010.

- ↑ "Forth Rail Bridge facts and figures". Forth Bridges Visitors Centre Trust. http://www.forthbridges.org.uk/railleaguetable.htm. Retrieved 2 September 2010.

- ↑ 5.0 5.1 Langmead, Donald; Garnaut, Christine (2001) (Google Books). Encyclopedia of Architectural and Engineering Feats (3 ed.). ABC-CLIO. p. 119. ISBN 157607112X. http://books.google.com/?id=T5J6GKvGbmMC&pg=PA119. Retrieved 2009-03-06.

- ↑ Plank, Roger; McEvoy, Michael; Steel Construction Institute (1993). "Forth Railway Bridge: First steel structure" (Google Books). Architecture and Construction in Steel (illustrated ed.). Taylor & Francis. p. 16. ISBN 0419176608. http://books.google.com/books?id=Y1hHkmy7Uz0C&pg=PA16. Retrieved 2009-03-06.

- ↑ http://www.scottish-places.info/features/featurefirst1053.html

- ↑ "Forth Rail Bridge Facts & Figures". Forth Bridges Visitors Centre Trust. Retrieved April 21, 2006.

- ↑ http://www.forthbridges.org.uk/railbridgefacts.htm

- ↑ "Rail bridge death toll increases". BBC News. 2006-09-04. http://news.bbc.co.uk/1/hi/scotland/edinburgh_and_east/5313128.stm. Retrieved 2007-05-16.

- ↑ Overview of Forth Bridge. The Gazetteer for Scotland. Retrieved 21 April 2006.

- ↑ http://bestbridge.net/Eu_en/forth-railway-bridge.html

- ↑ "The Forth Bridge". Forth Bridges Visitors Centre Trust. Retrieved 21 April 2006.

- ↑ "Balfour Beatty Awarded Forth Bridge Contract". Press Release. Balfour Beatty, 28 April 2002. Retrieved 21 April 2006.

- ↑ "be like painting the Forth Bridge". theFreeDictionary.com. http://idioms.thefreedictionary.com/be+like+painting+the+Forth+Bridge. Retrieved 23 November 2010.

- ↑ 16.0 16.1 Cramb, Auslan (18 February 2008). "Non-stop job of painting Forth Bridge to end". Daily Telegraph. http://www.telegraph.co.uk/news/uknews/1578986/Non-stop-job-of-painting-Forth-Bridge-to-end.html. Retrieved 16 January 2010.

- ↑ McKenna, John (19 February 2008). "Painting of Forth bridge to end". New Civil Engineer. http://www.nce.co.uk/painting-of-forth-bridge-to-end/754462.article. Retrieved 16 January 2010.

- ↑ "Rail bridge shuts for repair". BBC News. 4 July 2003. http://news.bbc.co.uk/1/hi/scotland/3043172.stm. Retrieved 16 January 2010.

- ↑ "Forth Bridge painting set to end". BBC News. 2008-02-18. http://news.bbc.co.uk/1/hi/scotland/edinburgh_and_east/7250560.stm. Retrieved 2008-02-18.

- ↑ http://www.transportscotland.gov.uk/reports/road/j8512a-05.htm#43

- ↑ http://www.stagecoachbus.com/fife/forthfastinfo.html

- ↑ http://www.sestran.gov.uk/news/article.php?ID=12

- ↑ "The United Kingdom £1 Coin". The Royal Mint. http://www.royalmint.com/Corporate/facts/coins/OnePoundCoin.aspx. Retrieved 2009-06-21.

- ↑ "Current Banknotes : Bank of Scotland". The Committee of Scottish Clearing Bankers. http://www.scotbanks.org.uk/banknotes_current_bank_of_scotland.php. Retrieved 2008-10-29.

- ↑ [1]

- ↑ Turing, Alan (October 1950), "Computing Machinery and Intelligence", Mind LIX (236): 433–460, doi:10.1093/mind/LIX.236.433, ISSN 0026-4423, http://loebner.net/Prizef/TuringArticle.html, retrieved 2008-08-18

- ↑ A North Sea Diary 1914-1918, p. 80

- ↑ "Grand Theft Auto Wiki - Kincaid Bridge". http://www.grandtheftwiki.com/Kincaid_Bridge.

Further reading

- Charles Matthew Norrie (1956). Bridging the Years - a short history of British Civil Engineering. Edward Arnold (Publishers) Ltd.

- Arnold Koerte, Firth of Forth, Firth of Tay, Birkhauser Verlag (1992), ISBN 0-8176-2444-9

- New Civil Engineer 5 February 2004, page 18.

- Peter R. Lewis, Beautiful Railway Bridge of the Silvery Tay: Reinvestigating the Tay Bridge Disaster of 1879, Tempus, 2004, ISBN 0-7524-3160-9.

- Charles McKean, Battle for the North: The Tay and Forth Bridges and the 19th Century Railway Wars, Granta Books, (August 7, 2006), ISBN 1-86207-852-1.

- Elspeth Wills, The Briggers - The Story of the Men who built the Forth Bridge, Birlinn, 2009, ISBN-978-1-84158-781-5.

External links

- Forth Bridges Visitor Centre Trust - Rail Bridge Main

- Forth Bridge Memorial

- Forth Rail Bridge at Structurae

- Poetry Map of Scotland Firth of Forth: "Construction of the Forth Bridge"

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||